LED ultraviolet lamp is a supporting product for dishwasher.

It is used to realize the lighting and sterilization effect in the dishwasher

Application

Used to realize the automatic lighting when the dishwasher is open, as well as switch controlled lighting. Moreover, it provides bactericidal function.

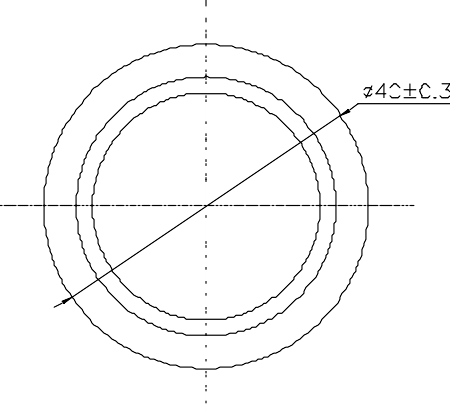

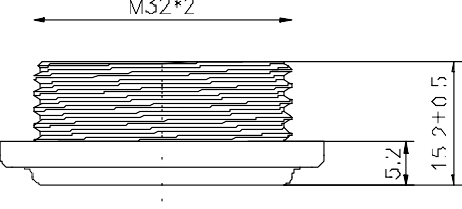

Dimension

Terminals, connectors, wiring harness length, wires are subject to the requirements agreed by both parties

Item

Name

Specification

Supplier

Certificate No.

Environmental friendly

1

Wire harness

TUOFU

YES

2

UV lamp bead

5.5-7.5V/40MA,3535,275nm/J275S35C

JIESHENG

YES

3

Purple lamp beads

2.8-3.3V/30MA,2835,400nm

JUFEI

YES

4

White lamp beads

6-6.6V/30MA,2835,6000-6500K

JUFEI

YES

5

lampshade

OUDI

YES

6

PCB

FR-4 board

YUNKAI

YES

Electrical Parameters:

1、Rated Voltage(forward)DC12±0.2V;Rated current(forward)40mA

2、White light color temperature:6000K±500K, purple light wavelength: 400nm, UV light: 275~280nm

3、white light luminous flux:≥18lm。

4、Use a high-voltage test equipment with voltmeter accuracy not less than 5%, the leakage current is at 0.5mA gear, and apply 1500V 50Hz or 1800V/s between the conductive part and the shell for 1 min. There should be no flashover or breakdown.

1.Low temperature

According to GB2423. 1 Test A ‘ The low temperature test method of the temperature gradient of the non-heat-dissipating test sample’, place the LED lamp in an environment of -20±2°C for 48 h, and recover for 1 h. There should be no cracking on the plastic parts. Apply the rated voltage to the LED lamp, all LED emitting diodes are emitting light. There is no obvious difference in color and brightness of each lamp.

2.High temperature

According to GB2423. 2 Test B ‘ The high temperature test method of the temperature gradient of the non-heat-dissipating test sample’, place the LED lamp in an environment of -85±2°C for 48h, and recover for 1 h. There should be no cracking on the plastic parts. Apply the rated voltage to the LED lamp, all LED emitting diodes are emitting light. There is no obvious difference in color and brightness of each lamp.

3.Thermal shock

According to GB/T 2423. 22 Na ‘Temperature change test method with specified change time’, put the LED lamp at high temperature 85±2°C for 30min; normal temperature 20±2°C for 30min; low temperature -20±3°C for 30 minutes. After a total of 20 cycles and 0.5h recovery, There should be no cracking on the plastic parts. Apply the rated voltage to the LED lamp, all LED emitting diodes are emitting light. There is no obvious difference in color and brightness of each lamp.

4.Consistent humidity and temperature

According to the method specified in GB2423. 3, place the LED lamp in an test chamber with a temperature of 40±2°C and a relative humidity of 93% for 48 hours. The insulation resistance should be greater than 2MQ in the chamber. After 30min recovery, apply the rated voltage to the LED lamp. All LED emitting diodes are emitting light. There is no obvious difference in color and brightness of each lamp.

5.Water resistance

Completely immerse the LED lamp in a water tank with a water temperature of 20±10℃. After 24 hours, remove all water drops from the LED lamp. The insulation resistance should be greater than 5MΩ and the product function is normal.

Mechanical performance:

1.Vibration test

Place the LED lamp on vibration bench, vibration frequency 10-55-10Hz amplitude 3mm X, Y and Z directions for 10 minutes each. There should be no damage on the LED lamp. All LED emitting diodes are emitting light. There is no obvious difference in color and brightness of each lamp.

2.Drop test

The product drops from a height of 30cm onto a 15*15*3cm wooden plate for three times. After the three drops, the functional test result is good. All LED emitting diodes are emitting light. There is no obvious difference in color and brightness of each lamp.

3.Lift test

After power on for 600 hours with rated conditions, all LED emitting diodes are emitting light. There is no obvious difference in color and brightness of each lamp.

comply with RoHS requirements.