Company:SELONG ELECTRIC CO.,LT

Device name:safety switch

Model and specification:DC5V/10mA

Manufacturer model: KM-19

Part code:17438000017241

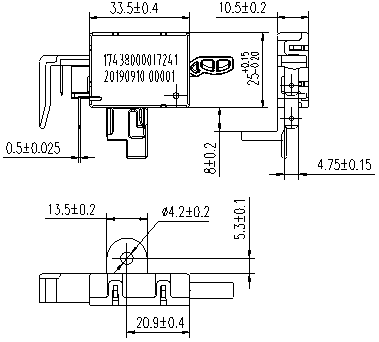

Dimension

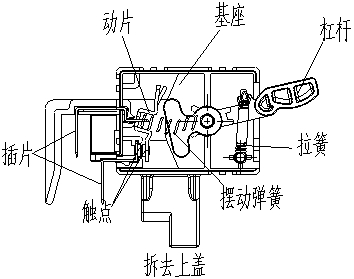

Structure

Key components

|

Item

|

Name

|

Requirements

|

Environmental friendly

|

|

1 |

Base mount

|

Reinforced fire proof nylon KPA66-25GF

|

Yes |

|

2 |

Moving plate

|

0.8 brass plate H62Y

|

Yes |

|

3 |

Lever

|

Reinforced fire proof nylon KPA66-25GF

|

Yes |

|

4 |

Swing spring

|

0.5 piano wire (blackened)

|

Yes |

|

5 |

Draw spring

|

0.4 piano wire (blackened)

|

Yes |

|

6 |

Cover

|

Reinforced fire proof nylon KPA66-25GF

|

Yes |

|

7 |

Contact point

|

AgNi(10)/Cu

|

Yes |

|

8 |

Pin

|

0.5 tin bronze plate QSn6.5-0.1Y

|

Yes |

Electrical Performance:

1、Rated Voltage: DC5V, Rated Current: 10mA

2、Withstand voltage: Apply AC1500V, 50Hz voltage between the conductive part and the non-conductive metal part for 1 min, while leakage current is at 0.5mA gear. There should be no flashover or breakdown.

3、Insulation resistance: The insulation resistance of live parts and exposed non-charged metals should not be less than 50MΩ when DC500V is applied.

4、Contact resistance: ≤30 mΩ (when the action stroke is 25mm)

5、Action position: 21mm±2mm; Disconnect position: 19.5mm±0.6mm.

Mechanical and environment Performance

1、No rust on metal surface, no crack or deformation on plastic surface, no exposed bottom, cracks, bubbles or shrink holes on internal coating. Markings should be clear.

2、Working temperature: 0℃~+85℃(T85); relative humidity 30%~85%.

Storage temperature: -15℃~+85℃; relative humidity 30%~95%.

3、Dimensions: should meet the requirements of relevant drawings.

4、Mechanical strength of the lead-out end: The lead-out end should be able to withstand 70N push and pull along the axial direction for 10s±1s, and the lead-out end should not be loose. Each lead-out end can only be tested once.

5、Flame resistance: non-metallic materials should have sufficient flame resistance and prevent combustion expansion. Should reach UL 94 V-0 level and glow wire 550℃±10℃ (if the test material is in contact with current-carrying parts, the glow wire should be heated to 850℃±10℃).

6、Life test: After the product is used 15,000 times under the rated voltage and current, the structure, the insulation resistance and electrical strength and the action characteristics meet technical requirements.

7、Thermal shock resistance: Place the product at a low temperature of -20°C for 1 hour and a high temperature of 85°C for 1 hour as one cycle. After 5 cycles, the insulation resistance and electrical strength meet technical requirements. The product can work normally.

8、Constant temperature and humidity performance: After placing the product at a temperature of 40℃±2℃ and a relative humidity of 93% for 96 hours, the insulation resistance measured directly in the test chamber should be greater than 2MΩ, and the insulation resistance and electrical strength meet technical requirements after 30 minutes of recovery. The product can work normally.

9、High temperature: Place the product at a high temperature condition of 85℃ for 75h, then place it in a normal temperature and humidity environment for 2h. The product should meet the insulation resistance and electrical strength requirements. The product can work normally.

10、Salt spray test: According to the method specified in GB/T 2423.17, place the working product in the salt spray box for 48h, where the temperature is 35℃±2℃, and the salt concentration is (5±0.1)%. There should not be rusty on metal parts.

11、Vibration: Apply a vibration with an amplitude of 2mm and a frequency of 16Hz~17Hz in the up and down, left and right, front and rear directions on the working product for 10 minutes. After vibration, the product should meet the insulation resistance and electrical strength requirements. The product can work normally.

12、Drop test: The packed product drops from a height of 50cm in an upright state onto a smooth, hard concrete floor for two times. After the two drops, there should be no abnormal results.

13、

RoHS Compliance

All parts and components shall meet the requirements of QMY-J11.001 "Technical Standards for Restricting the Use of Hazardous Substances in Drum Washing Machines"