SW series water level sensor is a component designed for checking water level. According to the water level, the product sends oscillation frequency to the appliance’s control board. It depends on the pressure, magnetic field, and electric signal to realize the function.

TEST CONDITIONS

1.Temperature: 25℃±5℃

2.Humidity: 45%~75%

3.Atmospheric pressure: 86kPa~106kPa

TECHNICAL REQUIREMENTS

|

TEST ITEM |

TECHNICAL REQUIREMENTS |

TEST METHOD |

INSTRUMENT |

|

Rated voltage |

DC5V±0.2V 10mA |

Measure |

Digital multimeter

|

|

Appearance |

No rust on metal surface, no crack or deformation on plastic surface, no exposed bottom, cracks, bubbles or shrink holes on internal coating. Markings should be clear.

|

Visual |

/ |

|

Rated temperature

|

﹣10℃~+60℃ |

Measure |

thermometer |

|

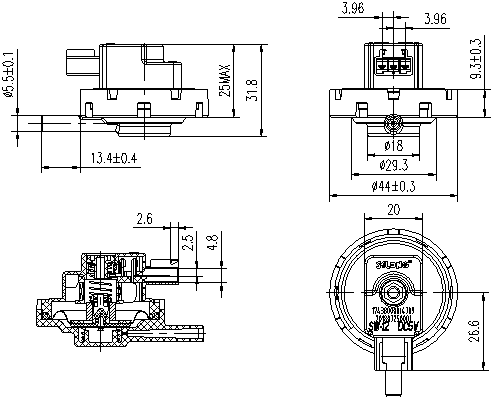

Dimension |

Meet the requirements of the specified values in the drawings or technical specifications |

Measure |

Vernier caliper/projector |

|

Curve

|

The frequency and its corresponding pressure relationship set under normal temperature and humidity should meet the requirements specified in the drawings or technical specifications

|

Measure |

Digital frequency meter pressure gauge |

|

Air tightness |

Measured with a standard water pressure gauge, pressurized for 1 minute at a pressure of 7.6kPa, the pressure sensor should not leak |

Test |

Air tightness test deck |

|

Electrical strength |

Apply 1500V, 50Hz, or 1800V/s between the conductive part of the pressure sensor and the mounting hole, and there should be no breakdown or flashover. |

Test |

Withstand Voltage Tester |

|

Insulation resistance

|

The insulation resistance between the conductive part and the exposed |

Test |

Insulation Resistance Tester |

|

High temperature |

After placing the product in a constant temperature test box at 70°C±2°C for 168h and placing it in room temperature and humidity for 0.5h, there should be no cracks in the plastic parts, and the water level change of each gear is less than 15mm

|

Test |

High and low temperature test chamber

Digital frequency meter

pressure gauge

|

|

Low temperature |

After placing the product in a constant temperature test box at -20°C±2°C for 168h, and placing it in room temperature and humidity for 0.5h, there should be no cracks in the plastic parts, and the water level change of each gear is less than 15mm |

Test |

High and low temperature test chamber

Digital frequency meter

pressure gauge

|

|

Thermal shock

|

Place the pressure sensor at a high temperature of 80°C±2°C for 1h, a room temperature of 20°C±2°C for 30 minutes, a low temperature of -20°C±3°C for 1 hour, totally 20 cycles. After recovery for 0.5 hours, the plastic parts should be free of cracks. The water level change of each gear is less than 15mm |

Test |

High and low temperature test chamber

Digital frequency meter

pressure gauge

|

|

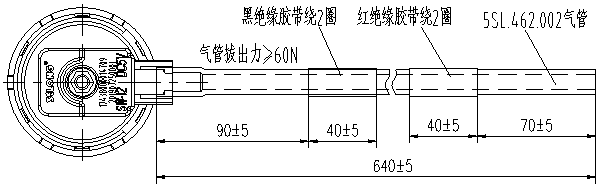

Nozzle strength |

Apply a tensile force of 50N on the air nozzle of the pressure sensor, upright, left and right directions respectively, and there will be no rupture or deformation after 5S |

Test |

Tension gauge |

|

High pressure |

Slowly pressurize from 0 to 15kPa at a pressure change rate of no more than 500Pa/S. After a 1-minute test, the pressure sensor should not leak |

Test |

Air tightness tester |

|

Water resistance |

After immersing the pressure sensor in a water tank with a water level of 10cm±1cm and a water temperature of 20℃±10℃ for 8 hours, the insulation resistance should be greater than 5MΩ after drying the water droplets. |

Test |

Water tank Insulation Resistance Tester |

|

Salty spray |

Place the working sensor in the salt spray box. After 48 hours, the metal parts must not be corroded, and the water level change of each gear is less than 15mm |

Test |

Salt spray test chamber

Digital frequency meter

pressure gauge

|

|

Humidity

|

After placing the pressure sensor at a temperature of 40℃±2℃ and a relative humidity of 95% for 168 hours, the insulation resistance measured directly in the test chamber should be greater than 2MΩ. After 30 minutes, the water level change of each gear should be less than 15mm. |

Test |

Constant temperature and humidity test chamber

Digital frequency meter

pressure gauge

Insulation Resistance Tester

|

|

Drop |

Drop the pressure sensor from a height of 30cm in any direction on a wooden board with a thickness of 20mm or more, a total of 3 times, the water level change of each gear is less than 15mm |

Test |

/ |

|

Durability |

After acting 50,000 times at a speed of 20 times/min under rated voltage, the water level change of each gear is less than 15mm |

Test |

Test deck |

|

Hazardous substance compliance |

For products that need to comply with hazardous substance restrictions, any parts on the product must meet the requirements |

Test |

Fluorescence analyzer |

|

Pulling force (applicable to pulsator ) |

Pull-off force of connecting pressure pipe and pressure sensor nozzle ≥60N

|

Test |

Tension gauge |

Installation and Inspection

The air nozzle is placed downward (as shown in below picture), and the action water level of each gear meets the technical requirements.

Appearance and frequency/water level

Frequency and water level correspondence

|

|

frequency kHz |

water level mm |

|

initial |

26.80±0.3 |

0 |

|

reset |

25.31 |

149±15 |

|

water level 1 |

24.89 |

190±13 |

|

water level 2 |

24.47 |

232±10 |

|

water level 3 |

24.02 |

282±10 |

|

water level 4 |

23.45 |

340±7 |

|

water level 5 CTQ |

23.01 |

390±7 |

|

high water level |

22.50 |

460±15 |